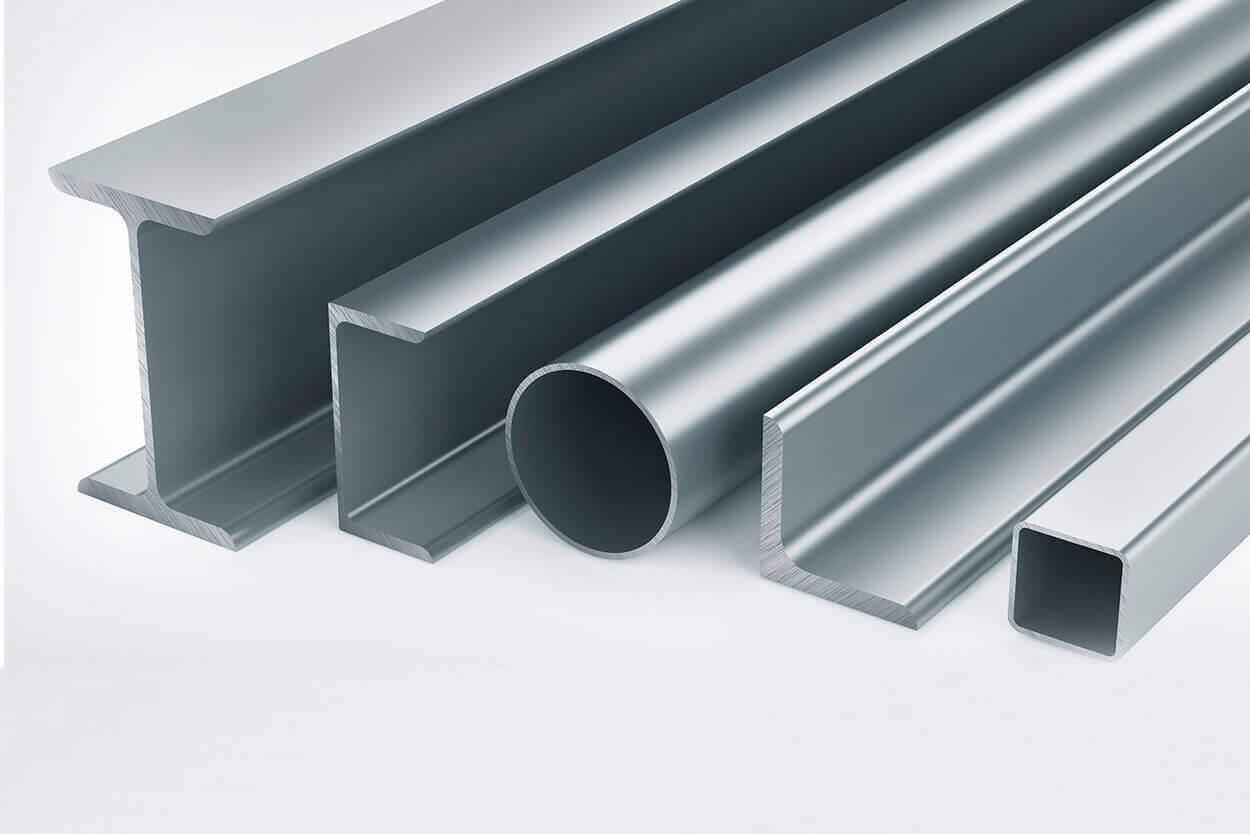

We provide total manufacturing solution of aluminum extrusion products.We can offer from aluminum extrusion, to surface finish, to machining, cutting and assembly. We also supply related parts or fitting (plastic molded or die casted).

With our experience we worked on several product groups:

Aluminum Motor Shell

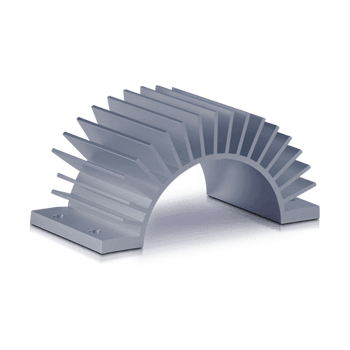

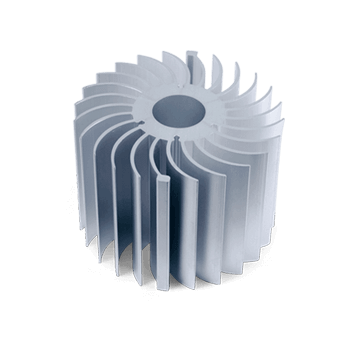

LED-Light Heat Sink

Aluminum Enclosure

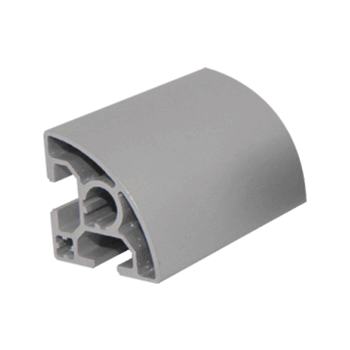

Profile for Office Furniture

Industrial Standard Profile

Cold Drawings

Cylinder, Square Tube

Aluminum Ladder

Aluminum Door / Windows

We are working with different aluminum alloy, depended on clients requirements and usage:

1XX.X SERIES - COMMERCIALLY PURE ALUMINUM (H)

Al alloy of 99% or higher purity. This series has excellent corrosion resistance, excellent workability, as well as high thermal and electrical conductivity.

2XX.X SERIES AL-CU ALLOYS (T)

Copper is used as the principle alloying element and can be strengthened through heat-treating. These alloys possess a good combination of high strength and toughness, but do not have the levels of atmospheric corrosion resistance as many other aluminum alloys.

3XX.X SERIES AL-MG OR SI-CU OR SI-MG-CU ALLOYS (H)

Magnesium is the major alloying element in this series, often with smaller amounts of magnesium added. 3003 is a popular alloy for general purpose because it has moderate strength and good workability and may be used in applications such as heat exchangers and cooking utensils.

4XX. X SERIES AL-SI ALLOYS (H)

Silicon is the alloying element, it lowers the melting point of aluminum, without producing brittleness. Because of this, this series produces excellent welding wire and brazing alloys where a lower melting point is required. (Structural and automotive applications)

5XX.X SERIES AL-MG ALLOYS (H)

Magnesium is the primary alloying agent. Alloys in this series possess moderate to high strength characteristics, as well as good weldablility and resistance to corrosion in the marine environment. (Building construction, storage tanks, pressure vessels and marine applications)

6XX.X SERIES AL-SN ALLOYS (T)

Alloys in this series contain silicon and magnesium. Extrusion products from the this series are the first choice for architectural and structural applications.

7XX.X SERIES AL-ZN ALLOYS (T)

Zinc is the primary alloying agent for this series, and when magnesium is added in a smaller amount, the result is a heat-treatable, very high strength alloy. Widely used in the aircraft industry or high quality wearable electronics and smart home products (Apple Watch).

8XX.X SERIES AL-SN ALLOYS (T)

Tin is the alloying element.

9XX.X SERIES AL + OTHER ELEMENTS (T)

(H) – Non heat-treatable alloys, (T) – Heat treatable alloys

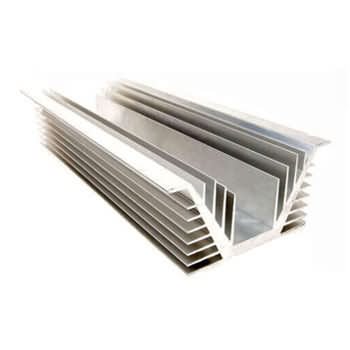

Examples of parts made of aluminum extrusion: