Precision, absolutely reliable quality, economical and environmental friendly manufacturing of large and small batches are our characteristics of the deep-drawn parts

They are made out of various metals and processed in secondary processes. The cleaned, electro-polished, galvanized or injection molded parts can be assembled individually or as components to the final product: in electronics and electrical engineering, in sanitation, in consumer products and automotive.

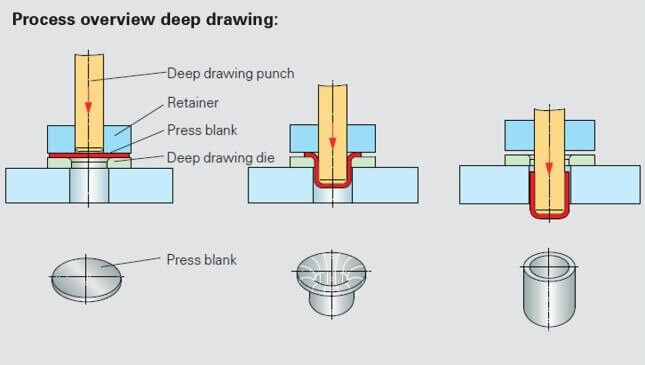

The deep - draw technology is a

qualitatively

economically and

environmentally

compelling solution. Even the smallest and thinnest parts can be manufactured precisely and the material utilization may be more than 80 percent - while keeping costs and the environmental impact equally low. In addition, deep drawing allows for very high stroke rates; This possibly increases the production rate compared to the metal-cutting process.

Deep drawing

is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.

Design and Engineering Support for Deep-Drawn Metal

With our experience, we offers design and engineering support for customers in need of deep drawn metal parts. Our team is ready to help you solve design challenges and answer your deep drawn process questions.

One stop solution

We know our customer needs and offer next to deep drawing also all manufacturer processes until assembling (with electromechanical parts) and packaging. We are looking for long term partnership with our clients.

Some of our for deep drawn product samples: