Metal forming

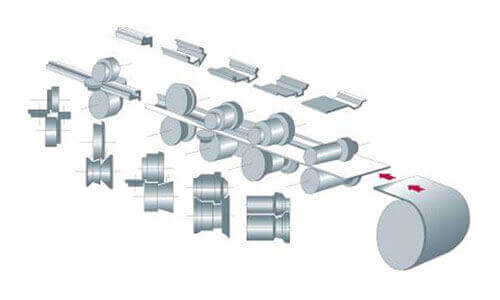

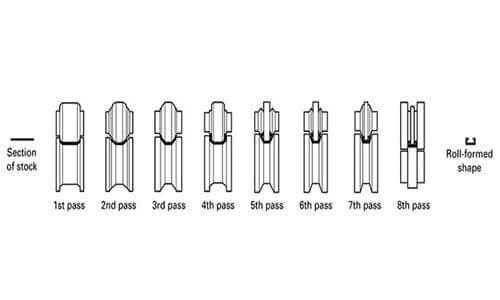

is the metalworking process of fashioning metal parts and objects through mechanical deformation; The work piece is reshaped without adding or removing material, and its mass remains unchanged. Our roll forming process begins by passing a long strip of coiled metal through a series of incremental bends until a final cross-section profile is achieved. Besides, our team of roll forming experts can apply further improvements.

Roll forming

Roll forming is ideal for economically producing high volumes of close tolerance parts with a wide range of geometries. Our roll forming process makes metals into hardened states so that lower labor costs can be reached.

Advantages of roll forming

Replace higher cost plastics and extruded parts

Reduce waste, secondary operations and labor costs

Compatible with both ferrous and non-ferrous metals

Fabricate finished or painted parts

Broad range of geometric opportunities

Roll forming capability

Roll forming machines are available that produce shapes of different sizes and material thicknesses using the same rolls. Variations in size are achieved by making the distances between the rolls variable by manual adjustment or computerized controls, allowing for rapid changeover. And, Tolerances can typically be held within ±0.015 inches (0.38 mm) for the width of the cross-sectional form, and ±0.060 inches (1.5 mm) for its depth.

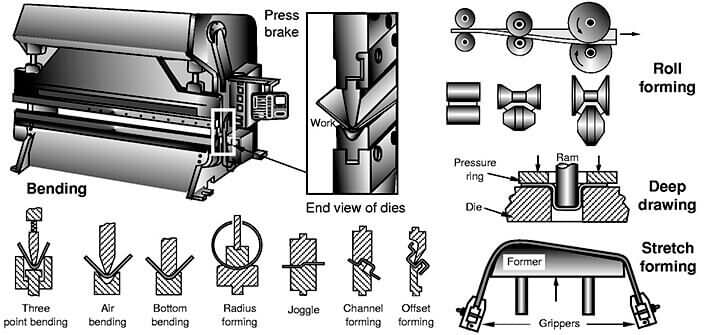

Compressive forming

Extrusion - where the material is pushed through an orifice

Die forming - where the material is stamped by a press around or onto a die

Forging - where the material is shaped by localized compressive forces

Intending - where a tool is pressed into the work piece

Tensile forming

Stretching - where a tensile load is applied along the longitudinal axis of the work piece

Expanding - where the circumference of a hollow body is increased by tangential loading

Recessing - where depressions and holes are formed through tensile loading

Combined Tensile and Compressive forming

Pulling through a die, deep drawing, spinning, flange forming, upset bulging, roll forming