Aluminum is an alloyed with copper, zinc, iron, magnesium, silicon and others. We offer following material choices: A356, A360, A380, A390, A383, A413, AlSi10Mg, ADC-12, ADC-14, LM4, LM6, LM9.

A356 is the most popular. A380 aluminum alloy is also widely used for casting general-purpose die castings. We would suggest some flexibility with raw material. For example: A383 is not as easy to find as A380 in China, and A380 can usually substitute A383.

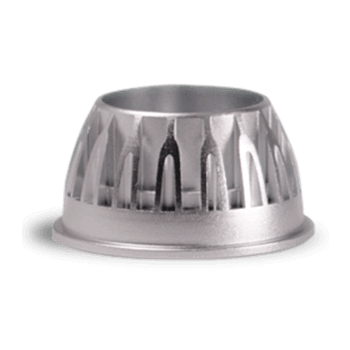

Aluminum Die-Casting

Aluminum die-castings are available in alloys including A380 and A383. Features of aluminum die-castings include thin wall, corrosion resistance, light weight, nice surface, and electrical conductivity.

Die casting utilizes 1 to 800 ton cold chambers with manual & automated operations. We have supplied aluminum die casting parts and enclosures to aerospace, military, electronic, medical markets.

Why use our Al die-casting products?

Thin wall

Corrosion resistance

Light weight

Nice surface

Electrical conductivity

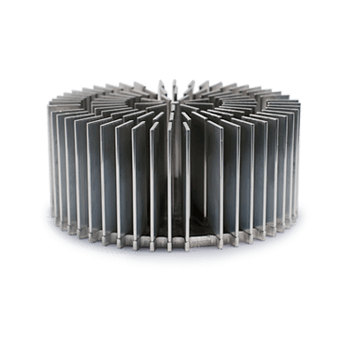

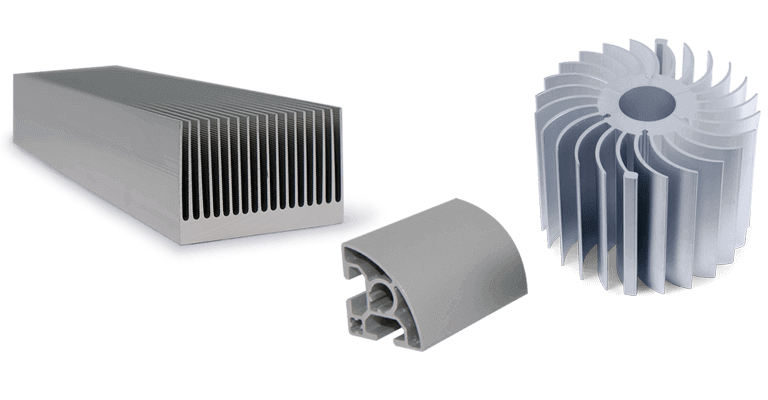

Aluminum Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section. The two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections, and to work materials that are brittle, because the material only encounters compressive and shear stresses. It also forms parts with an excellent surface finish.

Samples of parts made for OEM projects: