The last finishing of the products is very important.

Durability against environmental influences, corrosion resistance, smooth surface, long lasting or just good looking: we know how to treat the surface of your products according to your requirements.

Improve appearance, adhesion or wettability, chemical resistance, hardness, etc.

Modify electrical conductivity

Remove burrs and other surface flaws

Control the surface friction

Restore original dimensions to salvage or repair an item

Effects of some surface treatments on the metal:

Electroplating:

Increasing life of metal and prevents corrosion.

Polishing:

Creating a smooth and shiny surface.

Anodizing:

Increase the thickness of the natural oxide layer on the surface.

Powder Coating:

Making the surface into various colors.

Galvanizing:

Applying a protective zinc on surface to prevent rusting.

Sand Blasting:

Smoothing a rough surface, roughening a smooth surface,or removing surface contaminants.

Mill Finish:

Restoring to unfinished metal.

We use different kind of forming to achieve the most cost effective solution for our customer:

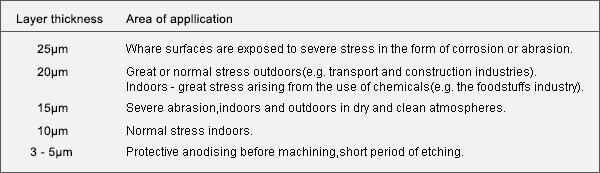

Our clients often require aluminum alloys anodized to increase corrosion resistance and to allow dying (coloring)

Painting or powder coating - gloss level from matt to high-gloss in all imaginable colors with modern equipment.

Polished surface – often required for brass and stainless steel surfaces. From mirror finishing to brushed surface.