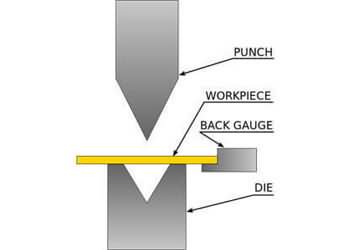

Sheet Bending

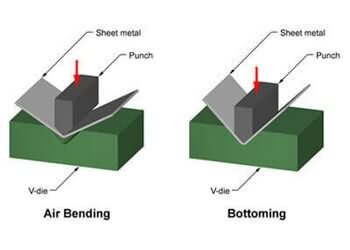

Air Bending

Air bending is the most common type of bending process used in sheet metal.In this process, the work piece is only in contact with the edge of the die and the tip of the punch.The benefits of air bending are as following:

Higher versatility with less tooling

Longer tooling life

Reduced part marking

Coining

Coining is a very basic type of bending in which the work piece is stamped between the punch and die. The material is put under enough pressure that the punch tip penetrates the material and it begins to flow into the die. It does however very large tonnages compared to Air Bending.

Excellent accuracy and repeatability

Require simple machines to execute

Bottom Bending

Bottom bending has similarities to both Air Bending and Coining. In this process the die angle should match the intended angle of the work piece, adjusting a few degrees for Spring Back, hence the existence of 88 degree tooling to achieve 90 degree angles.

Tube Bending

Tube bending is a kind of metal forming process which is used to permanently form pipes and tubes. According to different requirements, various treatments we used to provide you good- quality tubes with high accuracy.

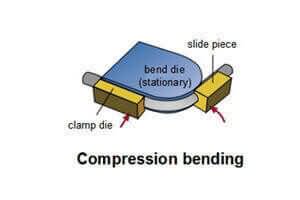

Compression bending

Compression bending is a rather simple method that is often used on production for bending electrical conduits. However, this type of bending has the limitation. It cannot make small-radius bends because the pipe will buckle or break.

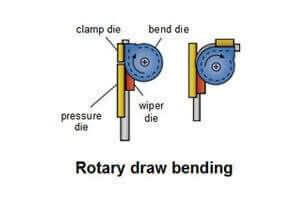

Rotary draw bending

Rotary draw bending is a method we use often, which allows for more control during the tube bending process as you use mandrels and dies inside the tube. It can:

Make a very tight bend with small dimensional tolerances.

Provide a smooth, aesthetically pleasing appearance which makes it an ideal for applications in which bend cosmetics are important.

Be used to bend square and rectangular tube and pipe, channel and extruded shapes.

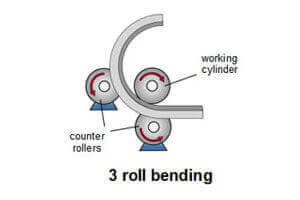

Three-Roll Push Bending

This method is the most commonly used freeform-bending process to manufacture bending geometries consisting of several plane bending curves. And, a 3D-shaping is possible. In a process, the profile is guided between bending-roll and supporting-rolls, while being pushed through the tools. The process is very flexible since with a unique tool set.

Some machines from our factory:

Some samples from our work for Bending: